Innovation

The foundation of our dedication to ongoing innovation and technological advancement is our research and development facility. Our R&D centre, housed within our Yamuna Nagar manufacturing complex, is dedicated to creating next-generation materials that satisfy changing industry demands while upholding our dedication to sustainability and performance excellence.

Infrastructure and R&D Capabilities

State-of-the-Art Laboratory Facilities:

- Advanced material testing equipment for comprehensive analysis

- Temperature and humidity-controlled environments

- Acoustic testing chambers for sound transmission evaluation

- Chemical resistance and ageing testing capabilities

- Prototype development and small-batch production facilities

Testing Equipment and Instrumentation:

- Tensile Testing Machine: 0-2000 kg capacity for material strength analysis

- Shore Hardness Tester: 1-100 A scale for durometer measurements

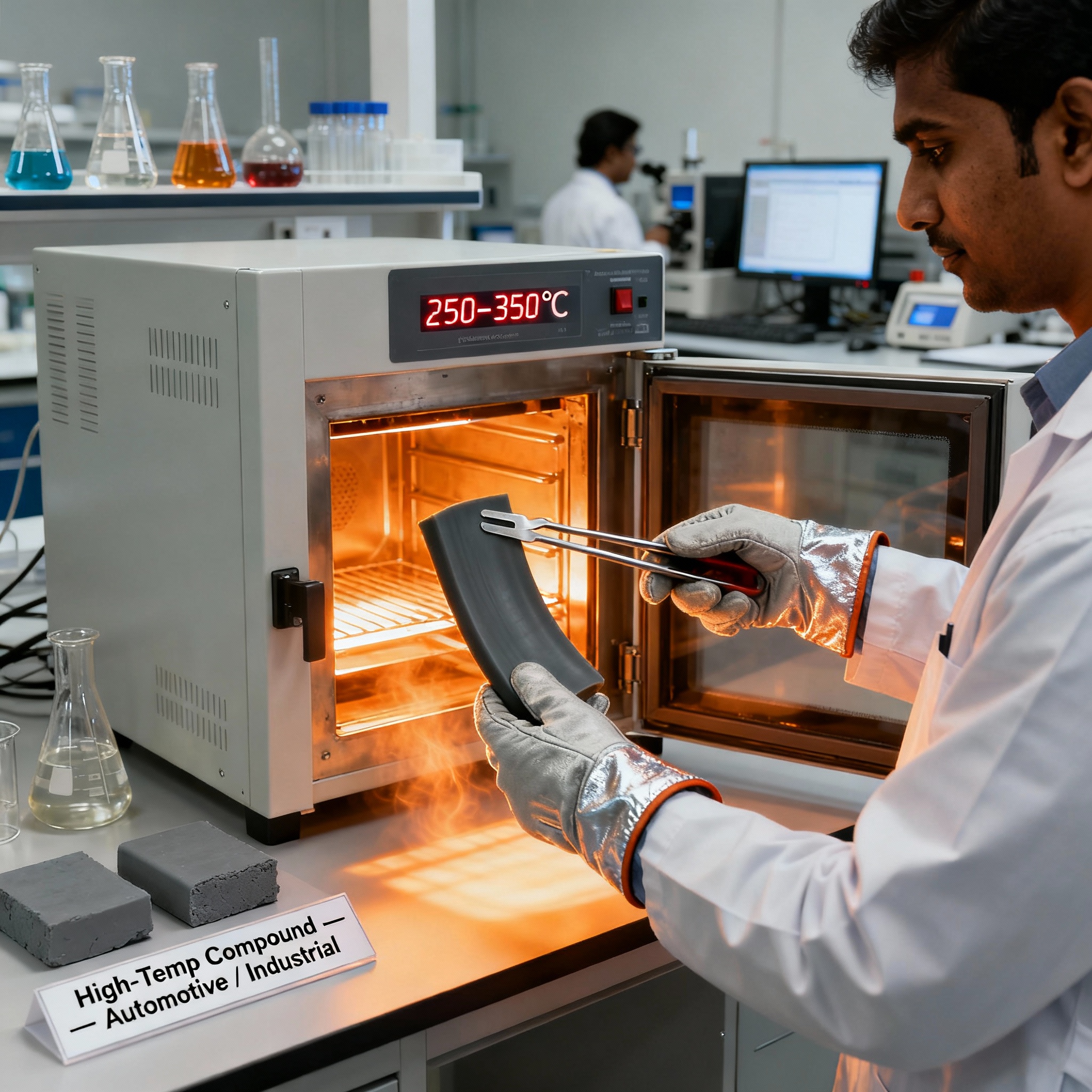

- Environmental Chambers: Temperature range from -10°C to 350°C

- Precision Measurement Tools: Vernier calipers (0-300mm range)

- Specialized Weighing Systems: From 1 gram to 2000 kg capacity

- Material Property Analyzers: For comprehensive material characterization

Quality Control Integration:

To guarantee constant quality and compliance with client requirements, our laboratory tests materials every hour during production, or twenty-four times a day. We can uphold the highest standards while assisting with efforts for continuous improvement thanks to this stringent testing procedure.

Focus Areas for Innovation

1. Advanced Material Formulations

- Creation of improved EVA compounds with better acoustics

- Extended weather resistance in EPDM formulations

- exceptional flexibility and durability in TPO/TPE materials

- specialised compounds for applications requiring high temperatures

2. Development of Sustainable Materials

- Compositions of recyclable materials

- Integration of bio-based content

- Formulations with less environmental impact

- Improvement of end-of-life recyclability

3. Customised Solutions

- Tailored formulations for particular application needs

- Specialized surface treatments and coatings

- Advanced multi-layer lamination technologies

- Performance optimisation for particular applications

4. Process innovation,

- Advanced manufacturing techniques

- Automation integration for increased consistency

- Energy-efficient production techniques, waste reduction

- Circular economy initiatives

Collaborative Development Programs

Collaborative Development Programs

We collaborate closely with our partners in the appliance and automotive industries to create materials that support their manufacturing processes and satisfy their unique performance needs. These cooperative partnerships have produced a number of creative solutions that give our clients a competitive edge.

Research Institution Collaborations:

- Collaborations with top technical universities

- joint research initiatives on cutting-edge materials

- Access to cutting-edge research methodologies

- knowledge-sharing initiatives with professionals in the field

Highlights of Recent Innovation

Sustainable Materials

Creation of 4-layer lamination capabilities that combine aluminium foil, felt, scrim, and PE film for improved performance attributes.

Technologies for Surface Treatment:

Application of corona treatment techniques that greatly enhance adhesion qualities for use in construction and automotive applications.

Particular Formulation Achievements:

Production of specialised compounds for applications requiring high temperatures, catering to clients in challenging environmental circumstances.